Crack Viewer

Deep Learning AI-based Image Inspection

Recently, due to the deterioration of social infrastructure, interest in safety inspection and maintenance has increased rapidly. In particular, in the case of concrete structures, damages that require repair, such as allowable crack width, are managed to suppress structural and environmental degradation. It is important to perform exterior safety inspection more effectively and to perform maintenance in a timely manner in order to manage the lifespan and secure safety of such social infrastructure.

"CrackViewer" is a deep learning based AI image analysis technique. It goes beyond the visual inspection of the structure, which was mostly visually dependent on manpower, and uses the collected images to automatically detect the presence of damage. It overcomes the manpower and access limitations of existing classical methods, contributing to effective safety checks by saving enormous manpower, time and cost.

Innovative solutions

Automatically detect type and

amount of damage

Structure damage inspection technology was mainly measuring the width of cracks visually, and it is extended to a program that can measure the length and area of damage. “Crack viewer”, deep learning AI-based image analysis solution is not only automatically analyzes defects such as cracks, efflorescene, pupils and peeling using captured images, but also provides quantitative data on the type and amount of damage.

Improved detection result

Deep learning AI based image analysis

Conventional rule-based image analysis techniques have the disadvantage of processing different procedures with different parameters depending on the type of damage in order to detect damage such as cracks, whites and peeling. Also, even for the same type of damage, detection results may vary greatly depending on the shooting quality or environment such as illuminance and focal length. Therefore, this technology specializes in morphology techniques for damage detection of structures and deeply improves damage detection results by conducting supervised learning according to damage types by applying deep learning based platform.

Effective application

Apply multiple image processing techniques

Image analysis can be divided into damage detection methods and techniques for learning feature points for detection. First of all, many effective image processing techniques and pattern recognition techniques, such as preprocessing through filtering, pattern recognition, image superposition recognition and shape detection, and combination, were considered to detect structural damage. These techniques can be effectively applied when the quality of captured images is poor or when image correction is required to extract certain elements.

Parameters optimization

Integrate image analysis procedures and supervised learning

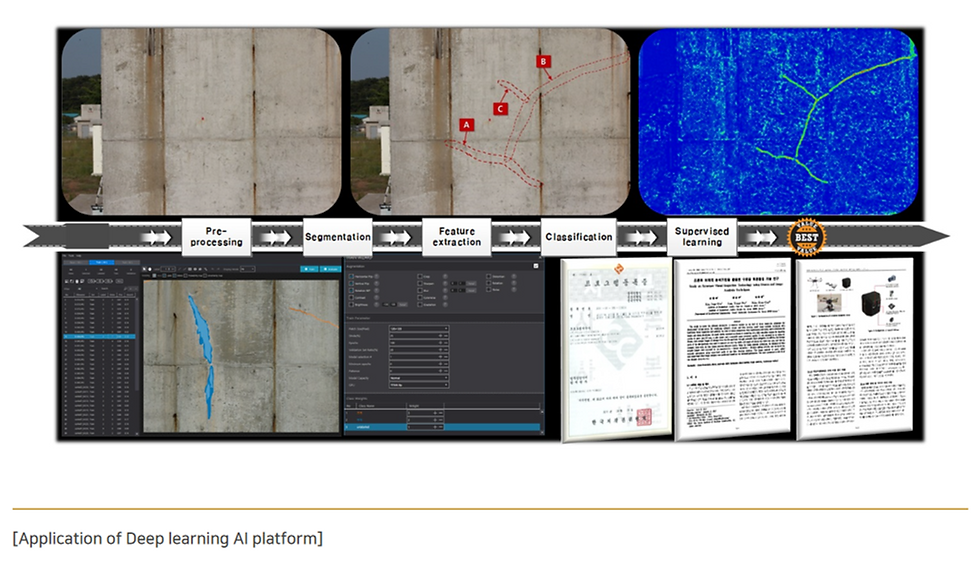

For image analysis, the damage is separated by Pre-processing-segmentation-feature extraction-classification-classification-supervised learning process using the collected original image. "Crack viewer" automatically extracts the best parameters for image analysis using supervised learning procedures with deep learning based platform

Damage Detection Process

Structure Exterior Damage Inspection

ㆍAutomatic analysis of exterior damage in concrete structures (cracks, efflorescene, pupils, and peeling)

ㆍSample Image Acquisition → Preprocessing → Separation → Map Learning → Feature Extraction → Classification → Processing

ㆍAcquired KCL patent report, compared with visual inspection, satisfies 92.5% of image analysis damage detection result

Structure Exterior Damage Inspection

ㆍPavement distress detection using deep learning techniques

ㆍDeep learning-based wall crack detection using hybrid image(Vision + IR camera)

ㆍNoncontact and nondestructive underground cavity(void) detection technique for urban sinkhole prevention

- Underground utilities mapping system(e.g. pipeline, manhole, etc.)

- Detecting the presence of cavity in the underground of the road using rider image analysis and evaluates cavity grade by automatically analyzing the risk

- Statistical analysis using 4,668,720 GPR A-scan waveforms(1D signal) for GPR data noise elimination

ㆍAutomatized underground cavity detection and utility mapping

ㆍ3D GPR data classification by 3D convolutional neural network

Patent & Certifications